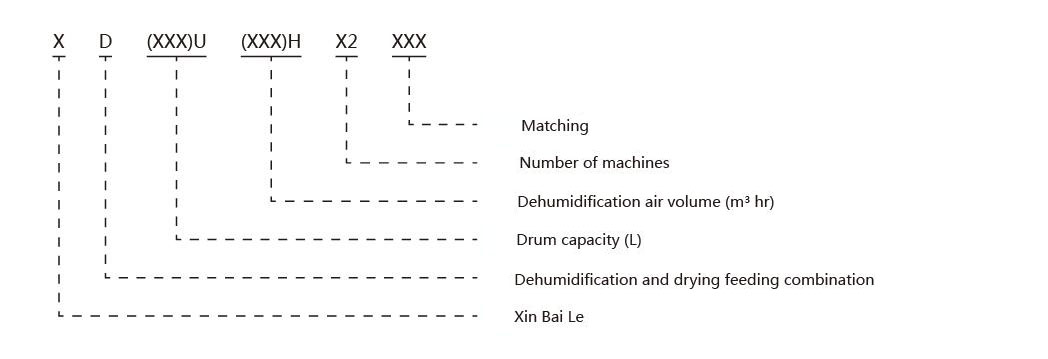

Dehumidification and Drying Feeding Combination

●The feeding system is equipped with a cut-off suction box to ensure that there is no residual raw material in the material pipe, so as to avoid raw material regains moisture

●The insulation drying barrel adopts the design of downblowing air pipe, matched with cyclone exhaust device, to avoid heat energy dissipation and improving drying efficiency

●The quantitative drying can quantify drying material by adjusting the position of the material level's induction switch according to the actual power on, so as to avoid problems like yellowing, brisk, lump and high energy consumption due to the characteristic change of the drying raw material

●Adopt molecular sieve honeycomb turning wheel, standard equipped Dewchecker, the dew point can reach -40℃

●The insulation drying barrel adopts the design of downblowing air pipe, matched with cyclone exhaust device, to avoid heat energy dissipation and improving drying efficiency

●The quantitative drying can quantify drying material by adjusting the position of the material level's induction switch according to the actual power on, so as to avoid problems like yellowing, brisk, lump and high energy consumption due to the characteristic change of the drying raw material

●Adopt molecular sieve honeycomb turning wheel, standard equipped Dewchecker, the dew point can reach -40℃